Things are a-changing Dec 6

When we start to come in to the fab, also known as the clean room, we have to go through two rooms. The pre-gowning room and gowning room. In the pre-gowning room you need to put a hair net, face mask, gloves and a beard net if needed. This room is also where you get your new clean room suit if yours is dirty/smelly or if you just want to change it. Our hair nets when we left last week looked like the traditional lunch lady hair net.

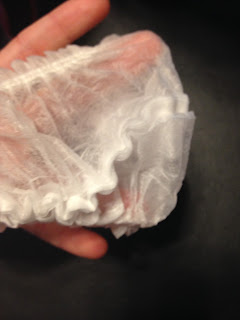

Today they were compacted and more snake-like

and you had to pull apart the middle to open it into the hairnet. It was interesting. The face masks smell like Iodine which goes away, or you get used to it, with 15 minutes. And the last new thing is, to me at least, the gloves feel thicker. Like the thickness of wearing two gloves, which since the gloves are large on me, and I already wear the smallest size, i wear two, so it felt like wearing three. It kept my hands warm. (Update 1/26/16- I think this week it was just a rouge batch of thicker gloves. they've gone back down to normal thickness, and the lunch lady hairnets only show up when the new ones are all gone and the next order isnt in yet)

Today while going through the pre-gowning room, I didn't notice anything different with the packaged uniforms, because I didn't look at them. I already had a suit hanging up in the gowning room. I got on my pre-gowning stuff and walked thru the next set of doors. When I got into the fab and at my bay, my passdown bay coworker from D1 said that on their shift at around 4:30p, they had a fire alarm go off and all had to evacuate. When the alarm goes off everyone has to leave the building with suit and all, which contaminates the suit and it cannot be worn back into the fab. No longer able to be used, It needs to be sent off to be cleaned. Since before i was hired, there has always been a shortage of suits available so a bunch of people had to take maintenance suits until the fab tech suits were cleaned. Maintenance wears blue, fab techs wear white. So there were a lot of blue suits walking about the lab, it was different. Sucks for those who dropped off their suits last week to be washed but didn't grab news one to hang before shift end, because they were wearing blue too. I did drop off my suit to be cleaned last week but grabbed a new one before leaving and hung it up because when they are freshly opened from the package, they smell like the chemicals used to clean them. So I let mine air out over the weekend.

Dec 7

Getting annoyed at most of the human population, going on day 12. I asked someone for a favor and so far as of today, after they promised to get it done that day... Than within that week, 12 days later they are maybe only 8% done with it. I don't know what they are doing all day as 'no' job is had by them. I do recall asking once why it wasn't being worked on and they answer was something along the lines of needing to mentally prepare themselves.

I got two write-ups that are not write-ups this day. They are called "Quality Awareness" forms. which when i explained what that meant i understood it as they are just forms that basically say "Hey. Pay attention. Slow down. Check yourself before you wreak yourself," and that they do not official go on record unless you do the same mistake again and get an official write-up, and they do no go to the board that reviews you for full time (from temp), promotions, bonuses and so on. I understood this as not effecting my chances of getting offered a full time, non-temp position. One Quality Awareness was for tracking out a product lot before the tool was completed. Which the tool is deceiving, because it says it is done with the product before it puts all the wafers back into the cassette. The second was for not noticing that our promise system said a cassette was only suppose to have 24 wafers, and the cassette had 25 in it. I was the only one that got in trouble on this one even tho there was three other steps before mine that no one noticed this mistake on either... But for some reason the company only punishes the one who last tracked out the product before it is caught. Lucky me.

In the last hour of shift, 72etch went down for a cooling plate error and in the last possible moment the maintenance man came to look at it. They fixed the problem and determined it need to be qualed before returning to production. Which I felt bad that we had to leave that for next shift.

Dec 8

At start of shift we came into 72etch working just fine. Just after passdown, it had a cooling plate error again. Once that was fixed it was back up for a few more hours than went down for a aborted recipe error because one of the wafers wouldn't process correctly. After that was fixed and our engineer processed the wafer, it was back up again... But when certain tools go down with product inside, they need their interface reset. But only sometimes. Apparently this was that time. The next 2 lots that were attempted to be tracked out, failed due to needing arbitrary 'data collection' because of the interfacing issue. Once that was fixed the engineer left for less than a minute and it went down again due to an endpoint not being reached in the recipe. We were done with it this sift and just left it to the next shift. It is getting closer and closer to shut down and less (if any) product is being started. If there are no starts than the new product doesn't go through ash or sink or anything. Less and less work is needing to be done each day. We made goals yesterday but I don't think we'll make goal tonight.

The ash work slowed to almost nothing at around 3 am. There were 18 lots between 3 - 6 am. The 34sink in Bay 4A was at a stop from 2-5:30a. Then 8 lots that came off the ash were able to run on 34sink. Other than 72etch giving us issues, the day was really slow.

Dec 9

For passdown D1 coworker said that he was running the bay alone, which is really really hard to do. Bu he also said it was easy for him because there was hardly any work to be done. My lead is out today and the step-in lead asked me to assist with running 28sink and 29sink because there was so little work to be done.

B4AG didn't show to work yesterday but didn't tell me or B4AT that he wasn't coming in. Which is fine. Everyone can keep secrets, it would have just been nice to know. We were told by our lead to found out at 6:30 he was off that day. When he came in today I said, "oh we didn't know you were going to be off yesterday". His response "well the Super knew". Helpful because the Super didn't tell us either.

Because of my recent maintenance man issues my lead let me know they were not going to be in on wed night shift and gave me the ext # of my super's desk in case the Super was not in the fab. I don't think the lead told anyone else except the Super and back up lead that they would be out the shift.

My super came up to me yesterday and just let me know that he was concerned and if I felt threatened or harassed, or if it got worse, to let my Super, my Super's boss or HR know. I said if it gets more aggressive to the point where it starts to bother me or if it continues after the shut down, I will be doing that. But right now it doesn't bother me. It's weird but easily ignored. I think the maintenance guy has stopped for now because he sees that I still don't acknowledge him.

Since Sunday I haven't had anymore issues with MMT. On Sunday every time he walked by he would shout "AJ!". Nothing Monday, nothing Tuesday, I thought he was done because during those days he didn't even look at me. Nope, started shouting "AJ!" again today near midshift. However he has been wearing his mask correctly. So maybe he did actually get in trouble or written up because a fabtech reported him??

One of my super nice coworkers from Bay 2A (B2aD) showed me a misaligned wafer print today. The numbers looked like they were ghosting one another

He said depending on how far back in layers it is it can either be scrubbed off and reworked or it needs to be scraped and restarted.

B4AG I think he needs to be taken off the ashers because he does not pay enough attention when unloading the cassettes from the ashers to the correct boxes. I was helping out 29sink again, so was not in my bay a lot. But 29sink from Bay 5A and 24sink from Bay 11D get most of their work from 4A ashers.

The B11DC came up to 4A to get work and dropped off 2 cassettes on his way past 5A. Then he came back 3 minutes later and said he had the wrong cassette in his box. This happened 2 more times during the night and the last time before we took work for the sinks, I checked the boxes because I noticed that there was a product cassette outside a box that should not have been. 6 boxes and cassettes were mixed up in this last switch up. It was a mess! I couldn’t even imagine what would happen if they went on and misprocessed.

3 more days till shut down.